The Canadian startup hijacks insects’ cellular machinery to change the way scientists work and open the door to a greener future.

You may think the annoying fruit fly buzzing around your kitchen is nothing more than a common pest, but you’d be dead wrong. As it turns out, fruit flies share 60 per cent of the same DNA as us and 75 per cent of the genes responsible for human diseases. They also evolve at an incredibly rapid pace—according to some studies, quick enough to respond to seasonal changes in their environments. This makes them ideal candidates for scientific research and, in particular, genetic studies.

In fact, fruit flies were the key to six Nobel Prizes. Over the decades, scientists have used fruit flies to study the origins and development of diseases including Alzheimer’s, Down’s syndrome, autism, and diabetes. They’ve also been used to learn more about hereditary traits, circadian rhythms, how to block the spread of cancerous cells, and even our sense of smell.

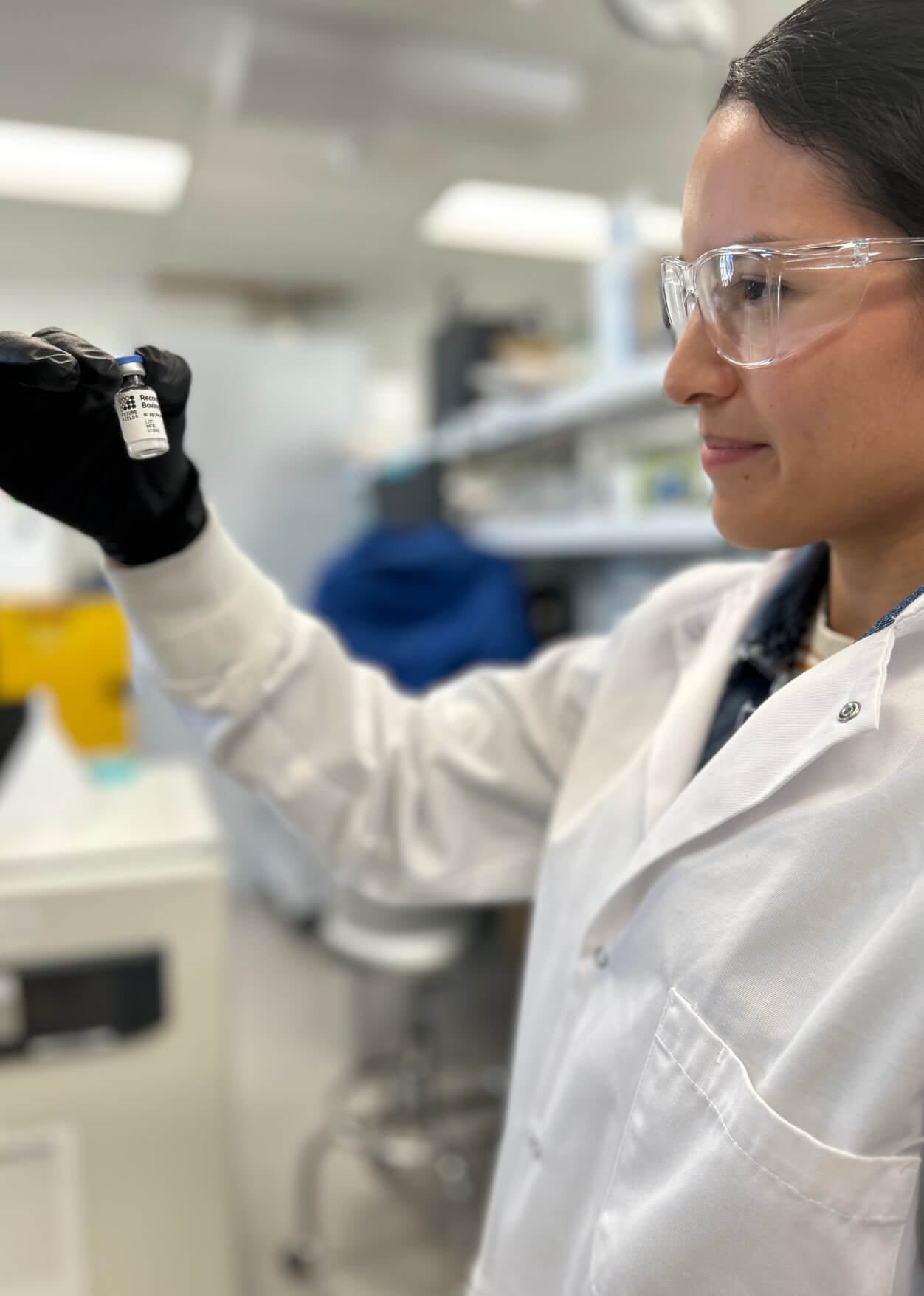

The fruit fly’s underrated, but distinguished scientific history is the backbone of Edmonton-based Future Fields’ innovative products. The startup, founded in 2018, uses fly biotechnology to create more sustainable and cost-effective recombinant proteins, which are used in a wide variety of applications, including by scientists to grow cell cultures. Recombinant proteins are a core component of biotech used in everything from biopharmaceutical experiments to stem cell research, fertility studies, food production, and more.

Future Fields’ ultimate goal: greener, more cost-effective biomanufacturing that protects the planet and turbocharges scientific advancements.

The story starts with chicken nuggets

Co-founders Matt Anderson-Baron and Jalene Anderson-Baron (yes, they’re married) originally set out to produce the first Canadian cellular agriculture chicken nugget by growing it in a lab rather than sourcing them from farms.. Why chicken nuggets? Because chicken is the most commonly consumed meat on the planet, and even five-year-olds like chicken nuggets.

Matt Anderson-Baron, co-founder & CEO, with Jalene Anderson-Baron, co-founder & COO

However, the duo quickly encountered a major hurdle. The growth factors they needed to make lab-produced chicken nuggets were too expensive to create a commercially viable product. So, they pivoted to solving the underlying problem of how to make more budget-friendly, sustainable growth factors.

At the time, Matt was finishing his PhD in cell biology, in which he did a lot of work with fruit flies. Jalene, who is now Future Fields’ COO, says she didn’t know much about what he was working on, however she did know they’re “an excellent model organism, and have a lot of applications in research.”

She was the one who raised the idea of using fruit flies to solve their problem, albeit not in the way they ended up doing so. “I think my original idea was to crush them up and sprinkle them into growth media as a supplement, which is not what we do,” she laughs. “But that was the spark for the idea.”

Matt, who is also Future Fields’ CEO, explains the idea evolved and now the company instead uses fruit flies as a vehicle for production. “We genetically engineer them to produce specific protein biomolecules that we then harvest,” he says.

While flies have been used by scientists for over 120 years, they’d never been used as a biomanufacturing platform before. “We get to stand on the shoulders of all these giants that came before us and did such amazing foundational work,” says Matt. “All that data and a lot of genetic tools are available that we, as a company, can leverage for this completely novel application.”

Welcome to the biorevolution

This one breakthrough is completely changing the way scientists conduct experiments and manufacture products. “The example most people would know is something like insulin,” says Matt. “For the last 50 years, the world created insulin by inserting the gene for insulin into microbes (yeast or E. coli), which are then grown in big stainless steel tanks called bioreactors. After a few weeks of growth, they can then harvest and purify the insulin protein.”

Future Fields eliminates the need for giant steel bioreactors, which guzzle energy and are very expensive to run, by using fruit flies to replace them. “We hijack the cellular machinery of the insect to produce a protein, then we rear those insects at large scale,” says Matt. “They’re grown in simple plastic containers that are very cheap and fed a cheap, scalable feedstock. Once we generate that biomass, we can harvest it and clarify the protein of interest from the resulting biomass.”

He says that, theoretically, they can do this with any protein.

Future Fields’ recombinant proteins both directly and indirectly contribute to sustainability. They allow labs to use significantly less energy and, by making scientific research and product manufacturing more affordable, they also help fields like cellular agriculture advance at a quicker pace and become commercially viable.

“By enabling cellular agriculture, we’re helping to create an industry that could address the more than 15 per cent of greenhouse gas emissions that come from animal agriculture”

“By enabling cellular agriculture, we’re helping to create an industry that could address the more than 15 per cent of greenhouse gas emissions that come from animal agriculture,” say Matt.

Jalene says their work at Future Fields is part of the biorevolution, a term that refers to “the rapid shift we’ve seen over the past few decades in our ability to manufacture everything from food, different types of materials, energy products, therapeutics, and pharmaceuticals using biology instead of traditional methods.” However, the biorevolution is far from over.

“It’s definitely still happening. I recently read a stat that we could theoretically manufacture up to 60 per cent of the inputs to our physical economy using biology,” says Jalene. “So, everything that we produce in the world right now, that much of it could be theoretically produced using biology. That’s pretty incredible.”

Married to the job, for better or for worse

Future Fields’ biotech is undeniably fascinating, but many people may find the idea of a husband and wife, also parents to a young child, co-founding and scaling a startup without one of them permanently sleeping on the couch even more extraordinary.

Matt and Jalene admit it’s not always easy. “I always tell people, being married to your co-founder is great for the company, but it’s hard on your marriage,” says Matt.

“Open communication, the ability to give feedback and sometimes have difficult conversations with your co-founder, is probably the most important thing for running a company”

There are undoubtedly some big benefits. “We can be more efficient. The number of meetings we have at home at 11 p.m. literally laying in bed, you can’t do that with anyone else. There’s also a level of transparency and honesty you need with your co-founder and you can ratched that up 100-fold with your life partner,” he says.

“One of the things we’ve learned is that open communication, the ability to give feedback and sometimes have difficult conversations with your co-founder, is probably the most important thing for running a company,” says Jalene.

However, the drawbacks include their marriage often getting “deprioritized because parenting comes first, then the company, then the marriage. It’s also hard to keep that work-life separation, but we do our best not to talk about work when our daughter is awake. We’re working on creating better boundaries there.”

Jalene says having a spouse as a co-founder also adds a different element of stress. “You’re both feeling the same stressors at the same time. It’s not like a conventional situation where there’s ebbs and flows in people’s work lives and, hopefully, the highs and lows aren’t always happening at the same time.”

Matt and Jalene’s own experience as parents helps shape their family-first approach to company culture and the flexible policies they offer around time off, vacation, and parental leaves. “I’ve always said, I don’t want to look back at this time and regret how we lived our life,” says Jalene. “We would never ever expect or want someone to miss out on any sort of family stuff like a Mother’s Day tea, or a piano recital or ever feel worried about taking time off to care for themselves or a family member.”

The Edmonton advantage

The duo credit being located in Edmonton, Alberta as part of their success story. “There are so many grassroots initiatives and organizations that make it a great place to build a startup,” says Matt. “Groups like Startup TNT and the group of people who created the YEG Startup Awards a couple years ago.” (Future Fields took home the YEG Startup Award for Best Startup Workplace in 2022 and was a finalist for Most Edmonton Startup of the Year in 2023.

“We’ve had great support from all three levels of government here, including really good access to grants,” says Jalene. “The city of Edmonton has been an amazing partner to us with everything from helping us navigate fire codes, business licenses, and all these complicated things we had to figure out for the first time when we were building our first headquarters.”

Speaking of those headquarters, Edmonton’s relative affordability is what made them possible. “Something that was really important in our early days was having access to affordable lab space. That’s something I don’t think is available in many cities,” says Jalene.

At one point, Future Fields won a contest to access lab space in Boston, but decided against doing so when they discovered how pricey it was. “A single 1000-square-foot lab would’ve been $60,000 a month,” remembers Matt. “That’s about eight times what we pay for an entire facility for ourselves in Edmonton.”

In their early days, they accessed lab space through Health Innovation Hub, a local incubator for entrepreneurs working on human health projects. “I honestly don’t know what we would have done if we weren’t able to do that,” says Jalene. “When you’re just starting out, you have an idea, but you need to actually prove it out. Yet you have no money, so it’s very hard to get access to a lab—you can’t just show up at a university and start working.”

Matt says their relationship with RBCx has also been important to their business journey. “Having a banking partner that understands venture-backed high growth companies, and the kind of a unique situation that we’re in, is really important to help us work on financial solutions. A lot of traditional banks don’t understand the nuances of how we operate versus how a more traditional business operates.”

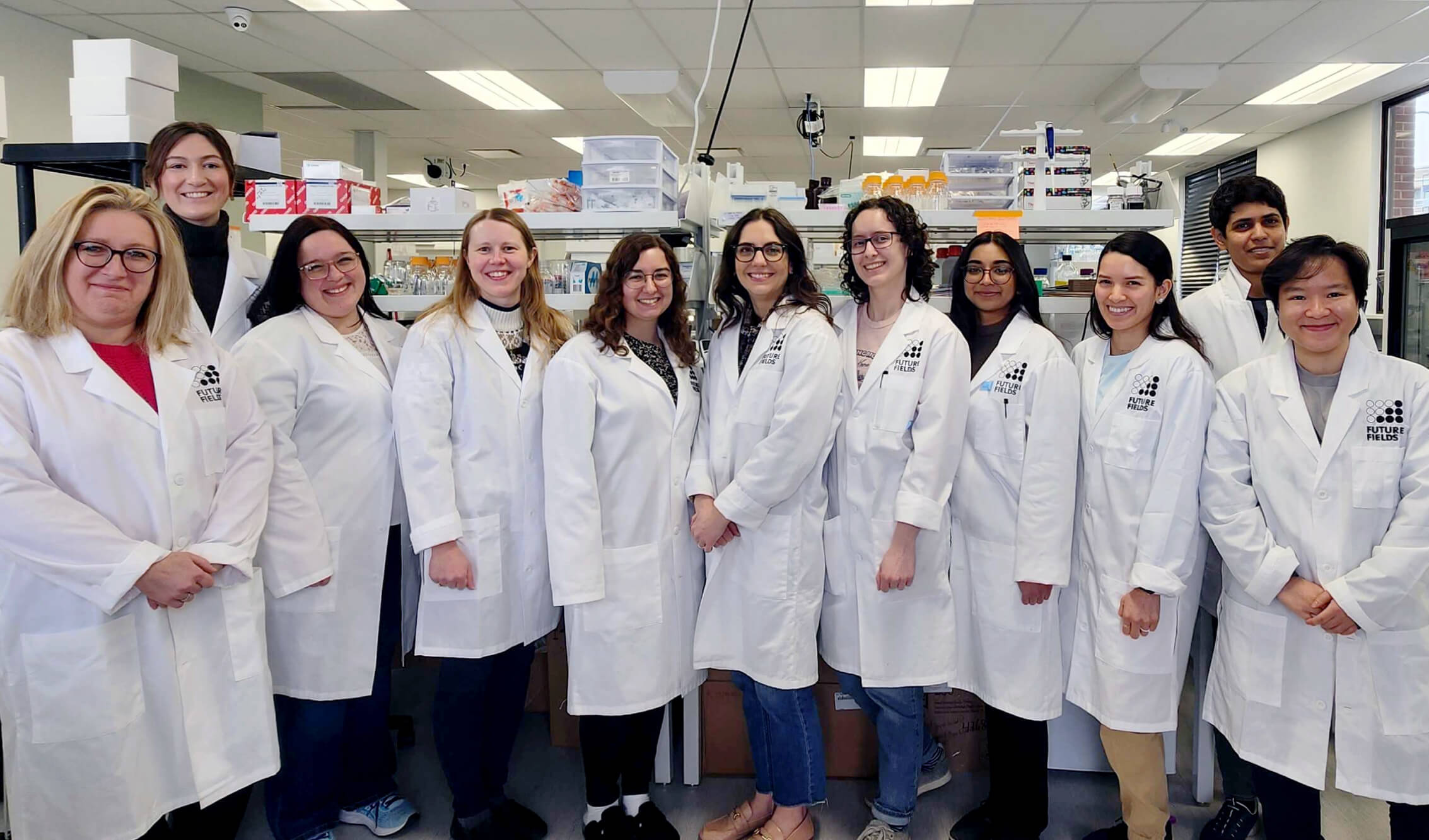

The Future Fields team in Edmonton

In just under five years, Future Fields has scaled quickly, and they’re just getting started. “We’re in the process of building out our pilot manufacturing facility, which is very exciting, because that will greatly increase our capacity for bio manufacturing, right in the heart of Edmonton,” says Jalene. “We’re going to grow our footprint, achieve higher quality, meet more regulatory thresholds, and access new markets.”

“We’re really excited for the next five years,” says Matt. “And beyond that, we’re excited to keep doing it here in Edmonton.”

To learn more about Future Fields, visit FutureFields.io.

RBCx backs some of Canada’s most daring tech companies and idea generators. We turn our experience, networks, and capital into your competitive advantage to help drive lasting change. Speak with a RBCx Technology Advisor to learn more about how we can help your business grow.